What really convinces arbitral tribunals? The delay expert’s view

30th December 2017

Geoff Bewsey describes his view that ‘the foundation of persuasive expert evidence is the expert’s independence and recognition that his role is to assist the tribunal’. He then describes three primary elements of the expert’s evidence necessary to convince the tribunal in matters concerning delay. Put simply, the delay expert must assist the tribunal to understand ‘what happened when, and why’. Based on scheduling practice, this requires a robust and well-evidenced as-built schedule showing when the tasks necessary to complete the project were carried out.

From an analysis of the as-built and baseline schedules, the expert must help the tribunal to understand the schedule of works and the tasks comprising the as-built critical path. The expert can show by analysis of the schedule that delays to certain intermediate activities are those that have resulted in delay to completion. Maintaining a distinction between the expert’s technical analysis and factual analysis, the expert assists the tribunal by providing a narrative referring to the evidence that the expert considers relevant to their opinion.

The delay expert’s view

Whilst the title for this seminar session refers to a ‘delay expert’, it is my view that this description is applied rather casually as few practitioners would claim that their expertise is in ‘delay’. Rather, expertise generally sought by the tribunal is in project planning and scheduling applied to analysis of delay. Thus, reference in this paper to a ‘delay expert’ indicates an expert with this skillset.

Communicating an understanding of the expert role

I refer here to the role of the independent expert witness as is widely understood in arbitration forums. I believe for the content of the expert’s evidence to convince the tribunal, it must first be convinced that the expert has understood the requirements and demands of independence.

This role is similarly described for various jurisdictions. I include below an extract from the current guidance of the English Courts. I have underlined the three particular aspects of the advice:

‘Duties and obligations of experts:

9. Experts always owe a duty to exercise reasonable skill and care to those instructing them, and to comply with any relevant professional code. However when they are instructed to give or prepare evidence for civil proceedings, they have an overriding duty to help the court on matters within their expertise (CPR 35.3). This duty overrides any obligation to the person instructing or paying them. Experts must not serve the exclusive interest of those who retain them.

10. Experts should be aware of the overriding objective that courts deal with cases justly and that they are under an obligation to assist the court in this respect. This includes dealing with cases proportionately (keeping the work and costs in proportion to the value and importance of the case to the parties), expeditiously and fairly (CPR 1.1).

11. Experts must provide opinions that are independent, regardless of the pressures of litigation. A useful test of ‘independence’ is that the expert would express the same opinion if given the same instructions by another party. Experts should not take it upon themselves to promote the point of view of the party instructing them or engage in the role of advocates or mediators.

12. Experts should confine their opinions to matters which are material to the disputes and provide opinions only in relation to matters that lie within their expertise. Experts should indicate without delay where particular questions or issues fall outside their expertise.

13. Experts should take into account all material facts before them. Their reports should set out those facts and any literature or material on which they have relied in forming their opinions. They should indicate if an opinion is provisional, or qualified, or where they consider that further information is required or if, for any other reason, they are not satisfied that an opinion can be expressed finally and without qualification.

14. Experts should inform those instructing them without delay of any change in their opinions on any material matter and the reasons for this (see also paragraphs 64-66).’

Whilst all of the above advice is relevant to the expert’s appointed task, the three points I wish to highlight here are that, in order to convince the tribunal that their evidence has weight, the expert should present their written and oral evidence such as to demonstrate that he:

- has carried out their investigations and analysis, and prepared their evidence, in order to help the tribunal on matters within their expertise;

- has provided opinions that are independent, unprejudiced by the pressures of arbitration; and

- is ready to re-appraise their opinions in the light of competing evidence or interpretation of facts.

Although I do not sit as an arbitrator, my colleagues who do advise me that they look to the expert witness to help them interpret the facts in evidence, thereby assisting them with the decisions they are required to make.

If it is evident to the tribunal that an expert’s motivation is to help their client rather than the tribunal — e.g. by seeking on occasion to ‘explain away’ competing facts rather than by considering their impact on their analysis — then the tribunal is likely to have less confidence in the expert’s independence and give less weight to the evidence.

In my own work as an expert, I constantly consider my evidence against the test ‘that the expert would express the same opinion if given the same instructions by another party’— in particular, whether this is what the tribunal will understand when reading my report or hearing my evidence. During report preparation, this reminds me to make sure that I have made clear how I have dealt with competing facts. This often leads to the inclusion of alternative analyses and an explanation of why I have preferred one outcome against another. In this, the tribunal is equipped to make decisions once they have decided on the facts.

Demonstrate what happened when, and why

Resolution of matters of delay in construction projects has been worrisome for a very long time. Accordingly, there are many publications giving guidance on methods and approaches to analysis of delay. Application by experts of the many and varied methods of analysis available has led many to describe the work of a delay analyst as akin to that of a magician whose art is an illusion, relying on ‘smoke and mirrors’ to give a perception of reality that is, at best, difficult to comprehend. Such a perception is entirely contrary to that which a tribunal requires.

Put simply, in matters of delay, the expert’s job is to assist the tribunal to understand what happened when, and why. Such understanding is unachievable if the tribunal cannot comprehend how the expert has carried out their analysis and came to their opinion. Where there are competing opinions, the tribunal needs to understand which of the experts has provided an analysis that is closer to a real explanation of the delays and their causes.

What happened when

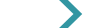

In my experience, the expert will best assist the tribunal when he first provides a robust explanation of ‘what happened when’. The delay expert’s primary tool to show this is generally to refer to it as an as-built schedule. In such a schedule, typically prepared in Gantt chart form in planning software such as Primavera P6, the expert provides a list of the tasks undertaken to implement the project showing the date on which each task starts and finishes. An example of a simple as-built schedule is shown in Figure 1, the construction tasks are listed in the column headed ‘Name’, each with an ID number in the column to the left, and each having its as-built start and finish dates displayed in the columns to the right. The blue bars in the chart area represent the activity period between the as-built start and finish date of each task.

The as-built start and finish dates relied upon come from the investigation of the project records. Investigations will generally start with seeking out and researching project documents, which enable the expert to form a chronological view of progress of the project. Typically, I seek first to find monthly or weekly project progress reports or meeting minutes as these, when available, generally provide a very useful overview of progress and of areas of concern recognised by the parties during the project. Such contemporaneous reports often include copies of updated schedules giving detail of activity progress and forecast criticality.

This initial research of documents and schedules will usually provide sufficient information to form a robust view of progress and criticality from time to time during the project period. The expert thus gains an understanding of key work areas and periods enabling detailed investigations to take place with proportionality. The further detail of start and finish dates of project tasks is likely to be found in project documents such as inspection records, notices, delivery records, labour allocations, site diaries and the like.

To demonstrate that the as-built schedule shows correctly ‘what happened when’, the expert must direct the tribunal to the evidence relied upon for each start and finish date shown. This will consist of a narrative to provide a chronological view of progress of the project works, and correlation of evidence to substantiate specific dates relied upon in the as-built schedule. For this, it is my practice to prepare a copy of the table at the left of the as-built schedule, and to list against each task the source of evidence for the start and finish dates relied upon. I typically provide this table as the front sheets of an appendix to my report, with copies of the documents relied upon collated and numbered in the same appendix. In this way, the tribunal is able to review and test the evidence underlying the schedule and to be convinced of its robustness as a record of ‘what happened when’.

… and why?

It is obvious that if a project, or its intermediate parts, were to finish on time, there would be no delay conundrum to resolve. In my experience, disputes regarding delay to construction projects invariably arise when a project milestone (or more than one) has not been achieved by the contractual date. The measurement of delay to a project milestone is generally (although not always) simple, being the difference between the contractual and actual dates for the milestone.

As a headline, the ‘why’ question can normally be considered ‘why did delay to the milestones occur?’ However, the answer to why there was delay to this milestone rests in understanding both the ‘when and why’ of delay for the intermediate tasks required to complete the project works and thus to achieve the milestone(s). The expert thus needs to provide the tribunal with a reliable tool for measuring delay to these other intermediate tasks required to implement the project and achieve completion.

Measuring delay

For this, the expert typically looks to identify a schedule, which reliably shows the contractor’s reasonable, original intentions for carrying out the works. Delay to the intermediate tasks can then be measured as the difference between the planned and actual start and finish dates for each. The schedule relied upon is typically referred to as a ‘baseline schedule’. When the tribunal is convinced of the relevance and probity of the baseline schedule, then it can proceed to rely upon it for measuring delay.

In my view, the NEC suite of contract forms defines well the fundamental functional requirements for a baseline schedule in this case in the negative, by setting out the reasons by which a schedule submitted for approval would not be acceptable. NEC3 clause 3 states:

‘A reason for not accepting a [schedule] is that the Contractor’s plans which it shows are not practicable; it does not show the information which this contract requires; it does not represent the Contractor’s plans realistically; or it does not comply with the Works Information.’

Working from these statements from NEC3, we may say that an acceptable schedule for use as a baseline for measuring delay should:

- show practicable planning for implementing the works — this means that the planned working methods and sequences must be practical and achievable;

- show the information which the contract requires — these may include such things as delivery milestones, dates for employer provided items, resources and the like;

- represent the Contractor’s plans realistically — this goes to probity of the schedule such that it should show what the contractor actually planned to do; and

- comply with the Works Information — for example the schedule should take account of phased access dates or restricted work periods.

The expert should investigate any schedule put forward by the parties as a baseline and explain to the tribunal the extent to which the schedule conforms to the above parameters. Even where there is a schedule for the works that has been agreed by the parties from the outset, the expert should assist the tribunal to understand the extent to which that schedule meets these criteria. In my experience, for projects that fall into dispute, there is often no schedule for the works that has been agreed by the parties from the outset, and it is necessary for the expert to investigate several schedules to identify the one, which, in their opinion, is the most suitable as the baseline schedule for analysis.

By explaining with rigour the basis on which the expert’s chosen baseline schedule should be accepted by the tribunal, the tribunal can then move forward to use the schedule as the basis for measuring delay to the project tasks.

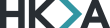

The expert will typically provide a variant of the chart at Figure 1 above in order to provide a graphic and tabular comparison of the baseline and as-built activity periods. The chart at Figure 2 shows such a comparison based on the chart at Figure 1. Figure 2 shows the same as-built information as the chart at Figure 1 with additional information as follows:

- two additional columns in the table showing dates for the baseline start and finish dates of the tasks; and

- yellow bars in the chart area representing the activity period between the baseline (or as-planned) start and finish date of each task.

I have prepared this simple example to illustrate the basic means by which a delay expert can use a schedule to analyse delay. Firstly, you can see by comparison of the yellow and blue triangles representing the completion milestone, and from the baseline and as-built dates, that completion was achieved six days later than planned. For this milestone, the baseline finish was to be 10 August 2006 but in the event, the as-built finish was 16 August 2006. Thus, the ‘what happened when’ question for this milestone simply states as ‘completion was achieved on 16 August 2006 which was six days later than planned’. As I have explained earlier, the ‘why’ question for this delay to completion is answered by investigation of the other, intermediate project tasks.

Inspection of the activity bars on the chart at Figure 2 shows that some as-built activity periods (dark blue bars) precede the baseline activity periods (yellow bars). This is the condition for many of the tasks of Building 2 (task IDs 16-19) and Building 3 (task IDs 23-27). The answer to the ‘what happened when’ question for these tasks is: ‘these tasks were implemented between one and four days earlier than was planned’. Clearly, implementing tasks earlier than had been planned does not explain why there was a delay in completion.

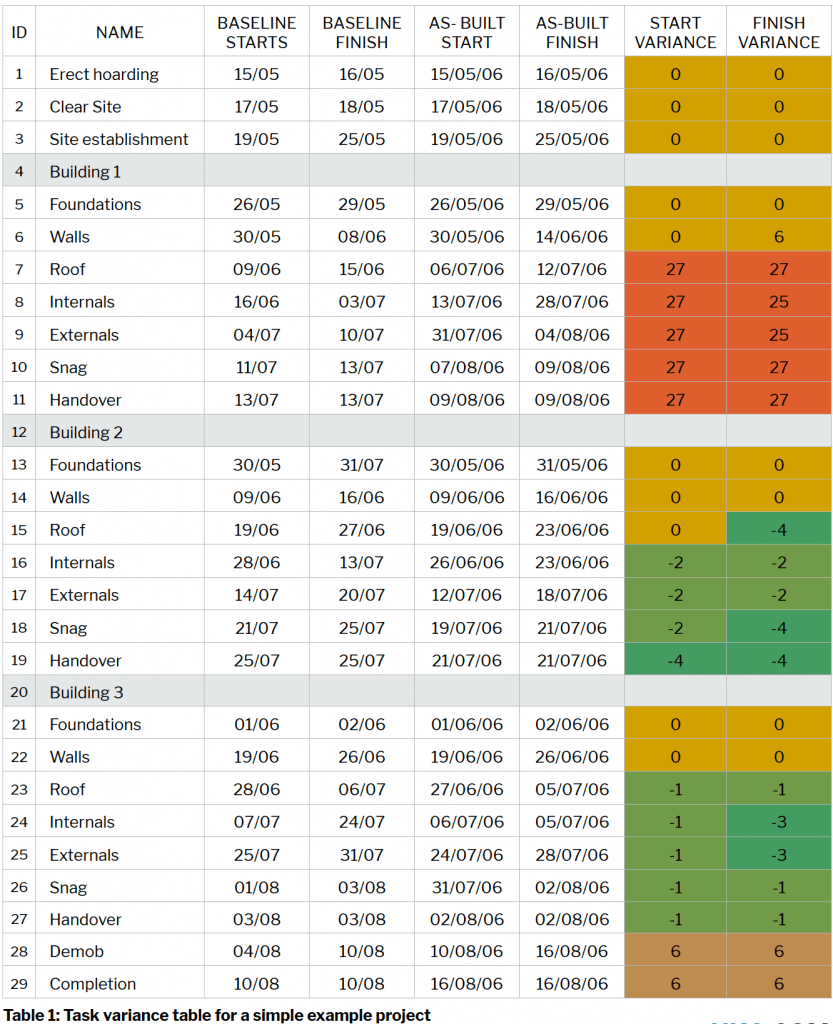

To provide full visibility of delay and mitigation, the expert can provide a task variance table, showing the start and finish date variance for each task. In Table 1 below (for an example project), I have applied a colour gradient, which highlights the greatest delay in bold red and the greatest mitigation in bold green.

Now, as you can see, five tasks of Building 1, from construction of the roof (ID 7) to handover (ID 11) were implemented much later than was planned. Comparison of the baseline and as-built dates for these tasks indicates delay of 25-27 days for these tasks. It appears, therefore, that delay to these tasks is that which has resulted in delay to completion, although further analysis of the schedule is necessary to understand why 27 days’ delay to Building 1 can have resulted in only six days’ delay to the completion milestone.

Schedule analysis – credible identification of the critical path

Further analysis of the schedule at Figure 2 is necessary to provide a credible explanation of how the identified delays to intermediate tasks resulted in the six days’ delay to completion. For this, the expert must identify the as-built critical path. This is the sequence of tasks, which, in the event, determined the overall duration of the project. To identify the as-built critical path, the expert will generally consider first the critical path of the baseline schedule. This provides an explanation of the Contractor’s planned methods for implementing the works.

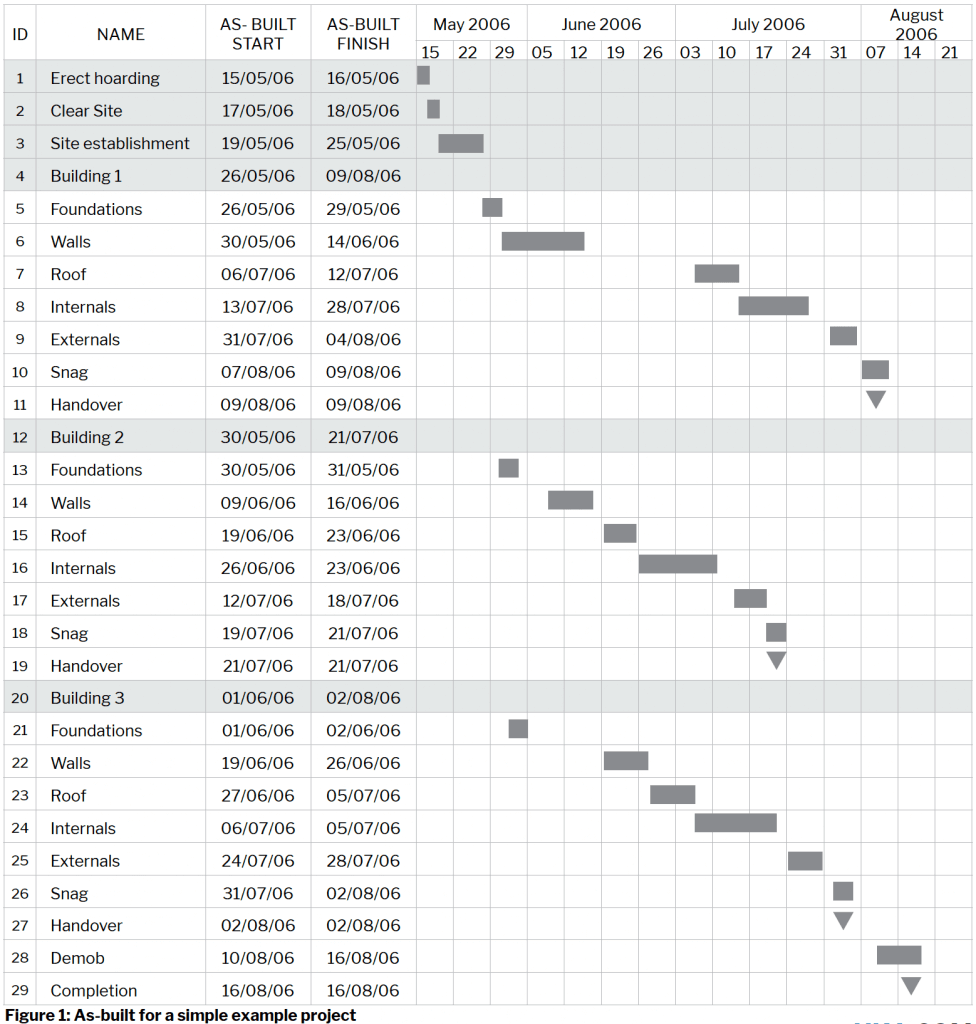

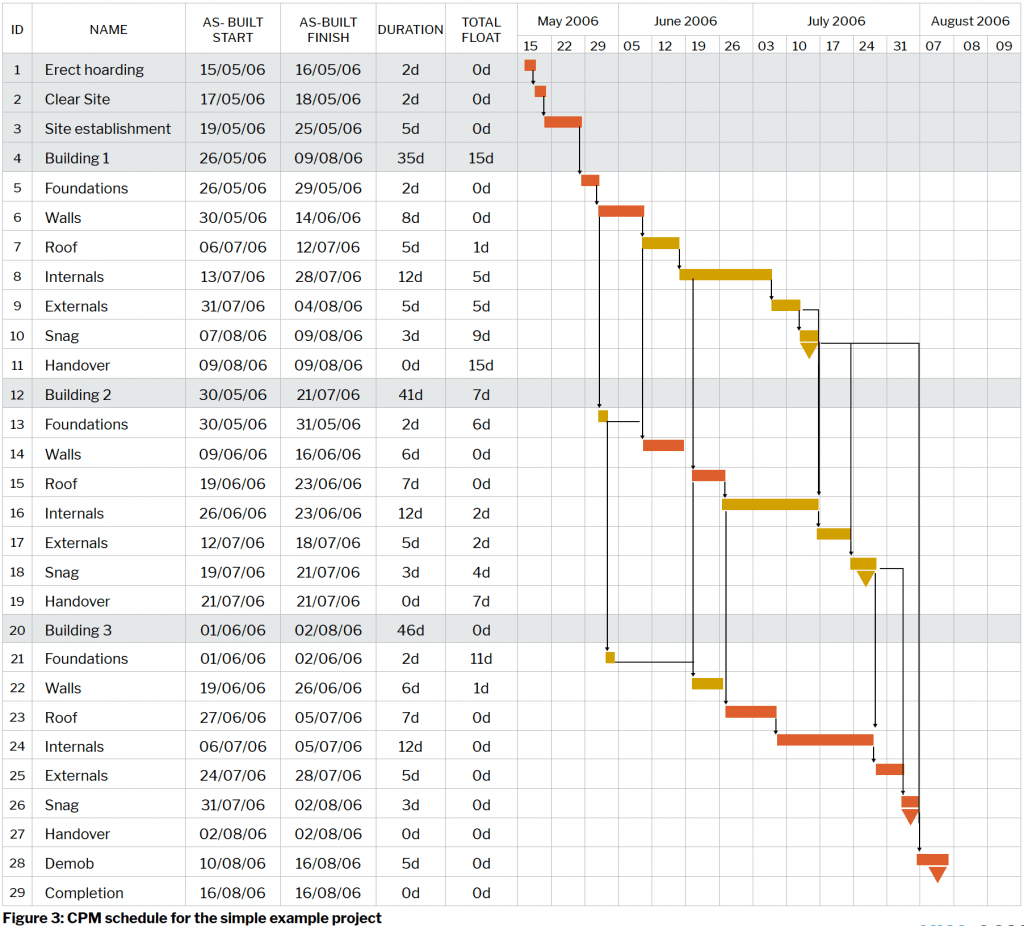

The chart at Figure 3 shows the planned schedule for the tasks of the example project shown at Figure 1 and Figure 2 above. The green and red activity bars on this chart show the same activity periods as the yellow bars at Figure 2. However, for this chart, the tasks shown as the prospective planned tasks for the works, in which condition the planning software can be used to show critical and non-critical tasks.

The critical path consists of the tasks whose sequence and timing determine the overall duration of the works. These can be seen as the tasks having ‘0d’ (i.e. zero days) displayed in the column headed ‘Total Float’1 . The activity bars for these tasks are coloured red. ‘“Float” between the tasks of a schedule’ can be considered as ‘unallocated time’. Where ‘Free Float’ exists between sequential tasks, the predecessor task can be delayed by the amount of its free float without causing delay to its successor. The ‘Total Float’ of a task is the amount by which it can be delayed without causing delay, via its sequential successors, to project completion. Tasks of the critical path have no float and, therefore, any delay to these tasks will, without re-planning, result in delay to completion.

By inspection of the chart at Figure 3, it can be discerned that the contractor intended to implement each of the seven sequential construction trade stages for each building, from foundations to handover, also in a sequence from building to building. Thus, it may be seen that the foundation works were planned to follow directly from building to building in sequence, i.e. Building 1, Building 2 and finally Building 3. A similar pattern can be seen for each construction trade stage and would be typical for relatively small, simple construction projects where a specialist trade subcontractor would carry out each construction stage. This is a ‘resource logic’ whereby the implementation relies on sequential use of resource and not only on the physical practicalities of construction.

Due to the varying duration of similar tasks in each building, after site establishment, the project critical path for the works as-planned materialises as follows:

- Building 1: Foundations then walls; then

- Building 2: Walls then roof; then

- Building 3: Roof through to handover; then

- Demobilisation and project completion.

A key point to note is that demobilisation (ID 28), i.e. removal of the contractor’s labour and equipment from site, commences after handover of Building 3 — the last building to be completed. Recognising this and the contractor’s plans for sequential construction trade stages from building to building enables discernment of the as-built critical path for the as-built schedule as at Figure 1 or Figure 2. In respect of building handover preceding demobilisation, it can be seen that the last actual handover before demobilisation was of Building 1 rather than Building 3 as-planned.

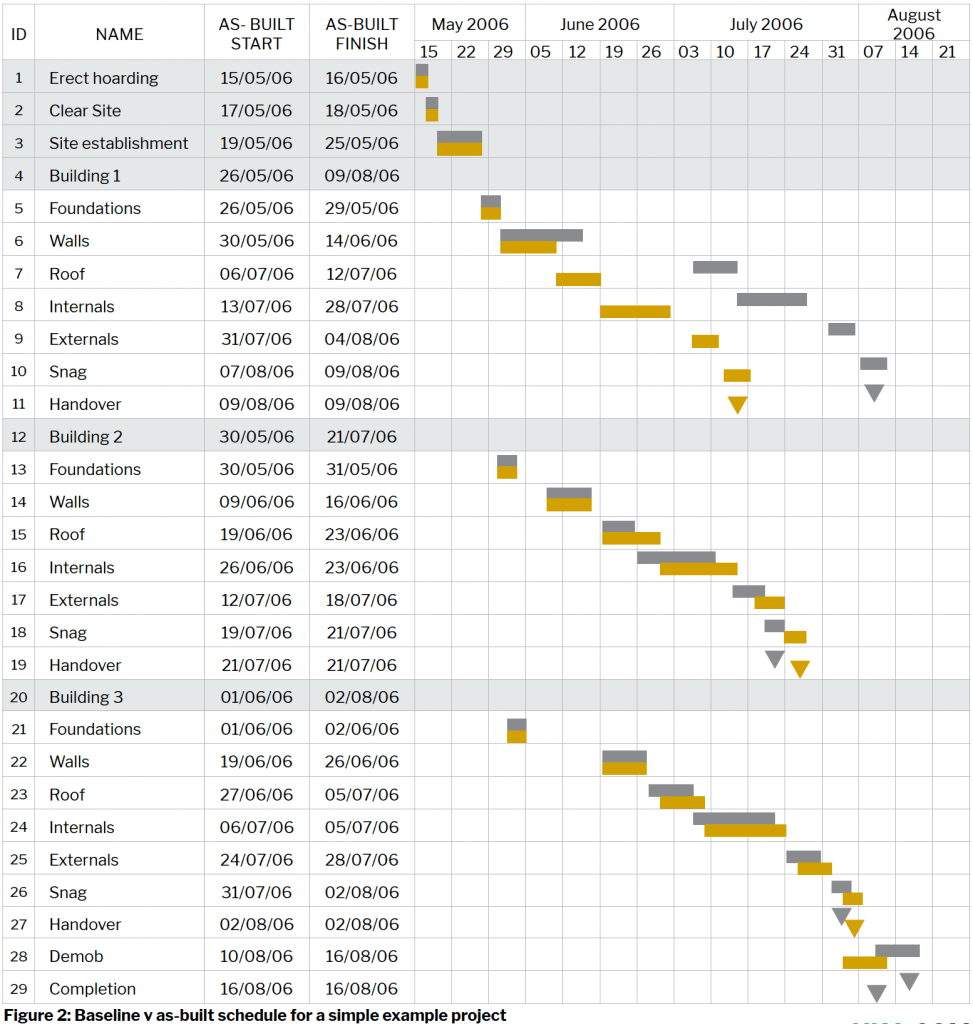

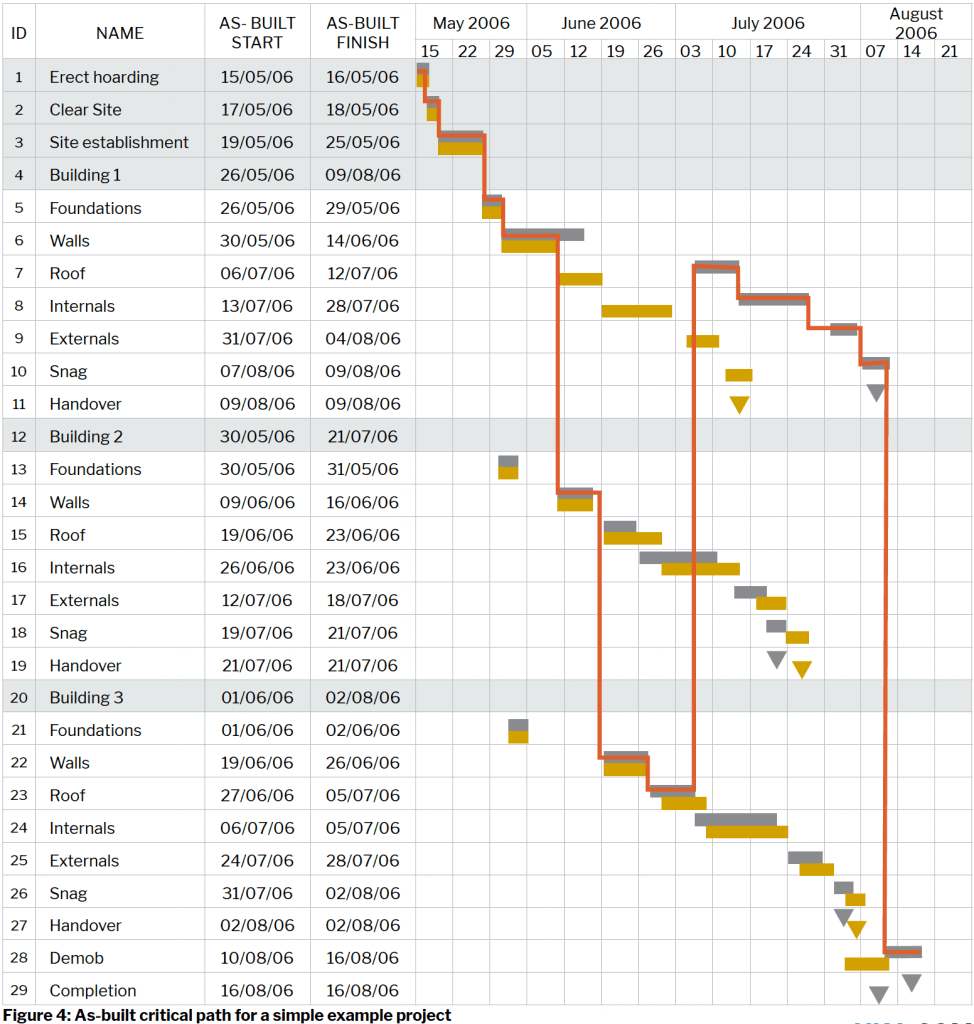

I have marked the as-built critical path thus assessed with a red line on the chart at Figure 4. Based on interpretation of the facts and on analysis of the schedule, the as-built critical path is part of the delay expert’s opinion evidence. Thus, in my opinion, after site establishment, the as-built critical path for the example project is as follows:

- Building 1: Foundations then walls; then

- Building 2: Walls; then

- Building 3: Walls then roof; then

- Building 1: Roof through to handover; then

- Demobilisation and project completion.

It can be seen by comparison of the baseline and as-built critical paths that the actual sequence of construction was different from that which was planned, construction of the roof for Building 1 being delayed until after completion of the roof for Building 3. By inspection, it seems that this change of sequence has resulted in the six-day delay to project completion.

To confirm this, the expert may check the planned float and the as-built delay to handover for Building 1. On the chart at Figure 3, the handover milestone for Building 1 (ID 11) shows 15 days’ Total Float. As noted, at footnote 2 above, the Total Float values displayed are based on a five-day working calendar and thus, as-planned, the handover milestone had three weeks, i.e. 21 days, of Total Float. As explained earlier, the as-planned handover of Building 1 could be delayed by 21 days without causing delay to project completion.

Comparison of the baseline and as-built dates for handover of Building 1 as shown at Figure 2 indicates a delay of 27 days to this milestone. Thus, since 21 days of delay to this milestone could accrue without causing delay to completion, this 27 days’ delay results in just six days’ delay to project completion. This is seen on the chart at Figure 2 as a delay to project completion of six days from 10 August 2006 as-planned to 16 August 2006 as-built.

Accordingly, in respect of time, the expert explains ‘why’ project completion was delayed by six days, namely that the sequence of construction was changed, whereby the construction of the roof for Building 1 was delayed until after completion of the roof for Building 3. Of course, this does not complete the chain of causation, as the reason for the delayed start of roof construction for Building 1 is not explained. For this, the delay expert will guide the tribunal to the evidence he has identified as relevant to the ‘why’ question by investigation of the matrix of factual evidence in project documents.

In my own work as an expert, I constantly consider my evidence against the test ‘that the expert would express the same opinion if given the same instructions by another party’— in particular, whether this is what the tribunal will understand when reading my report or hearing my evidence.

During report preparation, this reminds me to make sure that I have made clear how I have dealt with competing facts. This often leads to the inclusion of alternative analyses and an explanation of why I have preferred one outcome against another. In this, the tribunal is equipped to make decisions once they have decided on the facts.

Factual analysis – presentation of facts identified by investigation

In the first procedural order for a recent arbitration, I was the delay expert. The tribunal gave helpful guidance regarding the experts’ approach to the parties’ factual cases, as follows:

‘1. The Tribunal will expect each expert to base his or her opinion (in the alternative as required) on both Parties’ factual cases. No expert will give evidence on issues of fact (except direct evidence) or law, or on the sufficiency of proof of factual allegations.

2. Each expert’s report is to refer to all facts of which the expert is aware that are relevant to the opinions expressed, and is also to refer to any matter which would adversely affect the validity of those opinions.’

Fundamentally, the tribunal directed that the expert should provide analysis based upon the parties’ factual cases, leaving it for the tribunal to decide between the facts.

Now, it seems obvious that in order to provide their analysis, the expert must investigate the evidence provided by the parties. Here the expert also assists the tribunal to investigate widely the often very large volume of documents and, in their report, to ‘refer to all facts of which the expert is aware that are relevant to the opinions expressed’ and to ‘refer to any matter which would adversely affect the validity of those opinions’. The tribunal is unlikely to have the capacity to investigate all of the documentation in the case, and thus looks to the expert to do this and to point the tribunal to the relevant evidence.

In my view, the inclusion by the expert of reference to ‘any matter which would adversely affect the validity of those opinions’ is a further key element in convincing the tribunal of the value of the expert’s opinions. When the tribunal is able to understand how the expert has dealt with competing facts in forming their opinion, then the tribunal is assisted in making their decision between the facts. In my experience working in disputes, there have always been instances of facts which compete or appear to compete. Where an expert report makes no reference to competing facts in relation to any issue, in my view the tribunal is likely to question whether all facts have been duly considered.

Turning to consider the implications of the example above on causation of delay, and referring to the changed construction sequence and delay to the start of roofing for Building 1, the expert will need to investigate the evidence, primarily in documents, to identify the facts concerning this delay. The evidence underlying the as-built schedule and the critical path analysis and the variance between the as-planned and as-built tasks will guide the investigations.

Review of the baseline v as-built schedule at Figure 2, the baseline critical path at Figure 3 and the as-built critical path shown at Figure 4 leads me to consider the following as having potential to link with the cause of the delay:

- Construction of walls to Building 1 (ID 6) completed six days later than planned. The logic of the planned schedule was for the roof to Building 1 (ID 7) to commence after completion of the walls. It thus appears that the delayed finish of the walls would have delayed the start of the roof by at least six days, although in the event the actual delay to the roof was much greater. The circumstances of this delayed completion.

- Construction of walls to Building 2 started as planned, even though its predecessor task, the walls to Building 1, was delayed as above. Since the planned logic was not followed, it is likely that the actual circumstances at each at each building were not as originally envisaged. This also merits investigation.

- The sequence of roof construction started on Building 2 on 19 June 2006, which is 10 days later that the planned start of the roof sequence. It would appear that, had the contractor started with the roof on Building 1, immediately after the as-built finish of the walls for Building 1, the roof construction for the project would have started four days earlier, on 15 June 2006. I would expect a contractor to follow this action since this would have led to an earlier start of the roofs and therefore this circumstance also merits investigation.

It is not possible in this hypothetical scenario to provide more than a supposed factual matrix providing evidence of causation for the 27 days’ delay to the start of the roofs on Building 1, which resulted in the delay to project completion of six days. It is difficult to devise examples competing facts, and I shall not try to do so here. However, I set out below some supposed facts for illustration. Each would be accompanied in the expert’s report by the relevant document giving of the facts relied upon:

- An employer’s instruction was issued on 7 June steepening the roof pitch for Building 1, stating that the contractor’s design for this roof was deficient and therefore not approved, as it did not provide sufficient space in the roof void for the employer’s equipment to be installed after project completion.

- The contractor reverted by email on the same day, contesting the deficiency of their design. The contractor explained that this change required longer timbers for the roof construction than those already delivered to site in readiness for the roof subcontractor to commence as-planned on 9 June. The necessary longer timbers had been sourced but could not be delivered to site until week commencing 3 July.

- In the same email, the contractor gave notice that, if the employer wished to continue with the change to the roof of Building 1, this was likely to delay the completion of the project. As the contractor held the employer liable for the change, extension of time would be sought. The contractor undertook to investigate mitigating actions to minimise this delay and then to advise the employer further.

- By email late on 7 June, the subcontractor for the roof construction advised the contractor that the steepened roof incline for Building 1 would also require amendment of the brickwork / wall plate details at the top of the walls.

- By email on 8 June, the employer confirmed the change to the Building 1 roof was essential and that he held the contractor liable and requested the contractor’s proposal in respect of schedule to mitigate the effects of delay.

- Later that day, accepting the instruction but maintaining their position that this was an employer change with entitlement to extension of time, the contractor provided their schedule proposals as follows:

— The new timber for Building 1 would be ordered and delivered in week commencing 03 July.

— The subcontractor for the wall construction would provide additional labour on 12 and 13 June to make the necessary changes to the top of the walls to Building 1.

— The planned construction sequence for roofs would be changed and the work for the roof subcontractor deferred to start on the roof of Building 2 on 19 June as was originally planned for this roof.

— Starting thus with the roofs, all trade subcontractors would now follow the sequence Building 2 then Building 3 then Building 1.

— It was anticipated that the new timber for Building 1 would be at site in time to allow a smooth flow of work from the roof of Building 3 to the roof of Building 1.

— Project completion would be delayed to at least 16 August 2006.

— The order for new timber is dated 9 June and emails of 8 June to the subcontractors for the walls and roofs advise that they were to follow the above schedule.

— The employer accepted the contractor’s schedule proposal in an email on 12 June advising that no extension of time was due as the change resulted from a contractor deficiency.

The delay expert may conclude this part of their report by saying ‘in my opinion the six day delay to project completion resulted from the change to the roof of Building 1, instigated by the employer’s instruction issued on 7 June 2006’.

Now it remains for the tribunal to consider the above facts and to decide whether these should be accepted as giving evidence that the six day delay to completion was indeed caused as the expert describes. In my view, the tribunal will be convinced of this if the expert’s schedule analysis and factual analysis have been prepared and presented such as to demonstrate rigor, care and independence.

It should be appreciated that the expert has not strayed into giving evidence on issues of fact or on the sufficiency of proof. Notably, the expert has not given opinion as to liability. This remains for the tribunal to decide, and may require the evidence of a technical expert to resolve.

About the author

Geoff Bewsey is a Partner at HKA with over 40 years of experience in design, contracting and consultancy in the engineering and construction industries. He is a specialist in planning, scheduling and analysis of delay and disruption on complex, major projects.

Geoff’s experience portfolio includes oil and gas facilities, power and process plants, roads and bridges, retail and industrial developments, as well as hospitals, education and other public buildings.

He moved into consultancy in 1999, drawing on his management and commercial experience in construction to advise clients on project management, dispute avoidance and bid management. Geoff has also assisted clients to establish record and control systems that enable responsive monitoring and management of production in their construction works, and provides support and training to clients concerning time management skills and procedures.

He has been appointed on many occasions as planning and scheduling expert on construction disputes in the UK, Europe and the Middle East and has given expert evidence in arbitration.

This publication presents the views, thoughts or opinions of the author and not necessarily those of HKA. Whilst we take every care to ensure the accuracy of this information at the time of publication, the content is not intended to deal with all aspects of the subject referred to, should not be relied upon and does not constitute advice of any kind. This publication is protected by copyright © 2024 HKA Global Ltd.