Cost engineers and transport infrastructure: The vital role cost engineers play in major projects

25th November 2017

In Australia, the Gold Coast Light Rail ran $350 million over budget. Parramatta Light Rail, not officially costed, is reported to have blown out from $2.5 billion to $3.5 billion, and WestConnex Motorway has crept up from $10 billion to $16.8 billion (The Australian December 2, 2016).

The assessment of cost overruns on Australian transport infrastructure projects varies between 5% and 52%, and depends on the number and types of examples undertaken by various studies. However, based on Grattan Institute Report (2016), in the past 15 years Australian transport infrastructure projects valued at $20 million or more, planned or built, have cost $28 billion more than their estimated costs. This is 24% more than announced.

This report also finds that scope changes only account for about 11% of cost overruns and the rest of the 89% attributable to other causes. The above findings represent a substantial gap between estimated and actual costs and demonstrates real opportunities for cost engineering skills. Unfortunately, government agencies do not recognise this skillset or widely utilise it in transport infrastructure projects.

Cost engineering is the application of scientific principles and techniques that are applied to problems of estimation, cost control, business planning and management science, profitability analysis, project management, and planning and scheduling.

The activities of a cost engineer represent four categories: cost estimating, planning and developing cost baseline, progress measurement, and cost control.

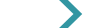

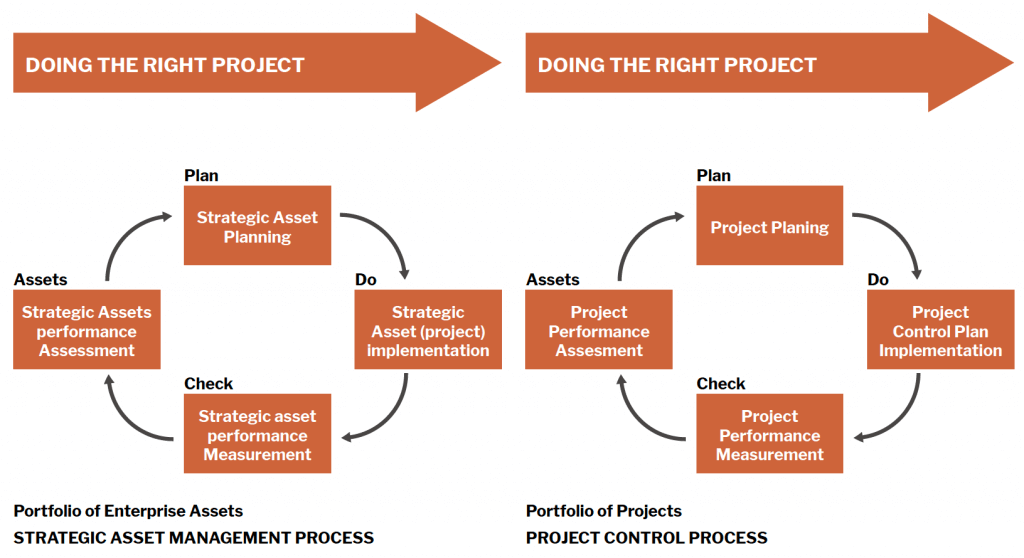

To achieve this, cost engineers rely on sound engineering practices such as engineering economics, statistics and probability analysis and employ the Total Cost Management Framework & Process (Figure 1 & 2) as the sum of the practices and processes to manage the total life cycle of cost investment in enterprise portfolio.

The knowledge and skills of cost engineering is widely recognised in the United Kingdom and the United States. Australian companies, particularly the government agencies, have not been able to establish the framework processes and develop capabilities required to utilise the skills and knowledge of cost engineers. Significant budget blowouts in capital infrastructure projects clearly demonstrate the scope to employ cost engineering skills in the rail and road projects and improve cost-forecasting practices.

Employing cost engineers at the very early stage including strategic assessment or business case development will enhance the maturity and accuracy of project funding and the appraisal process.

Their initial involvement will deliver huge benefits to transport projects through early establishment of a Total Cost Management Framework; allowing cost engineers to demonstrate a pathway to improve cost estimation and forecast practices for the entire project lifecycle.

Cost engineers knowledge of engineering economics, statistics and probability analysis will assist infrastructure programs to establish cost benchmark indexes based on the predictable patterns. It also enables delivery teams to base their estimates upon the cost model supported by historical evidence and lessons learned rather than the assumptions of project managers and estimators.

Major projects are the turning point with capturing the knowledge of cost engineering inevitable. According to the Grattan Institute Report, large complex projects are more prone to cost overruns as they tend to have many interdependent components that amplifies risk. Unlike small projects, project managers do not have the required competencies to manage the cost and contingency of the projects.

About the author

Kaveh Kia is a Lead Consultant at HKA. An industrial engineer with more than 17 years’ experience, he delivers project management services to major projects with multi-billion dollar values in the Australia and Middle East. Kaveh has a solid background in engineering, finance and project management along with a wealth of experience in project delivery, which enables him to offer wide range of solutions across the entire project life cycle.

Kaveh has an extensive background in both the infrastructure and resource sectors. During his career, he has contributed to a number of major projects including $34b Ichthys LNG, INPEX; $20.4 QGC LNG, Shell Australia; $2.5b Easing Sydney Congestion; $3b Gold coast Light Rail; $1.1b Moreton Bay Rail; $1b Sydney Trains More Train more services; $.3b Otway Gas Expansion, Origin Energy; $.3b Bass Gas Expansion; $2.4b Olympic Dam Infrastructure, BHP; $.4b Yandi Sustaining Project, Rio Tinto.

Major projects need to employ cost engineering specialist to better control the cost and put in place a comprehensive cost risk assessment system that project managers can’t implement independently.

Kaveh Kia, Lead Consultant

This publication presents the views, thoughts or opinions of the author and not necessarily those of HKA. Whilst we take every care to ensure the accuracy of this information at the time of publication, the content is not intended to deal with all aspects of the subject referred to, should not be relied upon and does not constitute advice of any kind. This publication is protected by copyright © 2024 HKA Global Ltd.