Anticipating material supply chain issues in construction projects

28th June 2022

Why is construction at risk of supply chain issues?

Recent news related to supply chain issues in construction has been sobering. One of the biggest reasons for this is that general contractors face increased risks related to cost escalation of numerous construction materials. It is expected that increased costs will be passed on to owners in the form of increased bid prices.

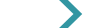

While U.S. Bureau of Labor Statistics data indicates that bid increases lagged for much of 2021, data from October 2021 to present, shown in the graph below, indicates that this is exactly what is beginning to happen. After lagging for a full year, bid price PPI has increased 17% since February 2021.

Figure 1: Construction Input vs Bid Price

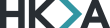

While inflation has been a widespread phenomenon, construction material input prices have been uniquely affected, outstripping other sectors. The graph below shows the average material price increase, with the construction-sector increases leading the pack.

Examples of how these price increases are detrimentally affecting projects are easy to come by.

In one example, a contractor contracted with an owner before both parties fully understood how a pandemic would impact the project’s material supply chain. Even in flush times, represents a difficult balancing act between production and distribution. COVID-related mill shutdowns, workforce disruptions, and other factors created material shortages, and prices spiked. However, the fixed-price contract did not include a material escalation clause and when material costs escalated, the burden of those increases rested on the contractor. The contractor finished the project at a tremendous loss.

In another case, a subcontractor locked in a price with a steel manufacturer with a six-month lead time. The steel manufacturer subsequently faced massive raw material price increases from the steel mill. Unable to absorb the increased material costs, the steel manufacturer went bankrupt. Subsequently, the subcontractor had to find another supplier, resulting in a substantial loss.

Whether the impacts are lack of workforce, inability to procure materials, or delays in procuring the materials, in light of current events it is essential for construction teams to protect themselves from working at a loss.

These nightmare construction supply chain issues are common in the current climate of the industry. Whether the impacts are lack of workforce, inability to procure materials, or delays in procuring the materials, it is essential for construction teams to protect themselves from working at a loss. This article lays out recommended contractual provisions to protect owners, contractors, and subcontractors, along with cohesive contractual methods for potential future implementation.

How to navigate construction supply chain issues

The First Line of Defense – the Contract

The contract is the most important document to manage supply chain issues and risks that may arise on the project. It needs to include several provisions to shield all parties in an amicable way when known and unknown issues arise on the project site. To assist construction teams, material escalation clauses or economic price adjustment clauses, force majeure clauses, notice provisions, and termination provisions should be utilised.

Material Escalation Clause/Economic Price Adjustment Clauses

Prices for construction materials are at multi-year or even all-time highs, and many price forecasts are indicating that prices may come back down. Prices, like the stock market, go down as well as up, and shrewd owners are beginning to realize that material escalation clauses can be in their fiscal interests.

All construction projects need to have a material escalation clause. A material escalation clause allows the parties to adjust the price and payment of materials based on an agreed upon metric. For example, the California Department of Transportation relies on the California Statewide Crude Oil Price Index for prices of paving asphalt. The Department maintains a historical record of this index on its website for parties to reference.

No party on a construction project is at fault for unforeseeable supply chain issues, and all parties need to work together to find an amicable provision that does not benefit only one side. Projects are completed as a team, and all team members must coordinate with one another to understand and deal with the risks equitably. Below are some ideas to manage material escalation risks:

- The parties can split the increased costs. The quoted material price can be cited in the contract and for any increase from that value, the parties can split the difference. A potential issue with this approach is that depending on the payment structure of the project, contractors and subcontractors may lose profits while assisting the owner funding the materials for the project.

- The burden can be on one party up to a certain percentage, and the risk can change after that percentage. The contract can provide that the contractor or subcontractor will pay for up to a certain percentage-increase of a material, say 10%, but once the price of that material goes past that percentage-threshold, the responsibility shifts to the owner to pay. One risk in this method is that material prices escalate significantly above the percentage-threshold, leaving the owner on-the-hook to pay for all those costs. This could be alleviated by incorporating a cap to the owner’s sole-responsibility (for example the owner might be responsible for increases from 10% to 20%), and if prices escalate beyond 20%, those costs are the shared responsibility of both owner and contractor.

- Time Adjustment. If there is an unanticipated critical delay in receiving materials, the contract should also address the time impact of the materials and the contract schedule can be adjusted due to the delay in deliveries.

The American Institute of Architects (“AIA”) offers contract templates that address material cost increases through allowances. For example, AIA Contract Sample A201-2007, Section 3.8 discusses Allowances:

Ҥ3.8.1 The Contractor shall include in the Contract Sum all allowances stated in the Contract Documents. Items covered by allowances shall be supplied for such amounts and by such persons or entities as the Owner may direct, but the Contractor shall not be required to employ persons or entities to whom the Contractor has reasonable objection.

§3.8.2 Unless otherwise provided in the Contract Documents,

.1 allowances shall cover the cost to the Contractor of materials and equipment delivered at the site and all required taxes, less applicable trade discounts;

.2 Contractor’s costs for unloading and handling the site, labor, installation costs, overhead, profit, and other expenses contemplated for stated allowance amounts shall be included in the Contract Sum but not in the allowance; and

.3 whenever costs are more than or less than allowances, the Contract Sum shall be adjusted accordingly by Change Order. The amount of the Change Order shall reflect (1) the difference between actual costs and allowances under Section 3.8.2.1 and (2) changes in Contractor’s costs under Section 3.8.2.2.”

Under the AIA approach, allowances for certain items must be discussed in the Contract Documents and must be approved by the owner in a change order. While the AIA can be used as guidance, sophisticated parties can creatively design their own material escalation clauses as they see fit for each construction project.

Prime contractors should be mindful to pass along fair terms to subcontractors. Consider, if a prime contractor cannot manage the current risk environment, there is little chance a subcontractor will be able to manage it. Regardless of the contractor level, a default or termination for failure to perform will likely result in significant disruption to the project for all parties.

Force Majeure

Delays caused by events such as floods or war can be excusable if there is a Force Majeure (or Act of God) provision in the contract. Most contracts include some form of a Force Majeure clause. While material escalations are unlikely to be considered force majeure, material shortages can be included in force majeure provisions. If the parties agree to include material shortages, make sure that it is expressly included in the force majeure clause. An example of a force majeure clause can be found in AIA Documents A201-2007:

“§8.3.1 If the Contractor is delayed at any time in the commencement or progress of the Work by (1) an act or neglect of the Owner or Architect, of an employee of either, or of a Separate Contractor; (2) by changes ordered in the Work; (3) by labor disputes, fire, unusual delay in deliveries, unavoidable casualties, adverse weather conditions documented in accordance with Section 15.1.6.2, or other causes beyond the Contractor’s control; (4) by delay authorized by the Owner pending mediation and binding dispute resolution; or (5) by other causes that the Contractor asserts, and the Architect determines, justify delay, then the Contract Time shall be extended for such reasonable time as the Architect may determine.”

As shown above, AIA A201 contemplates unusual delay in deliveries, but parties are free to tailor the provision and add material shortages.

Notice

As with other impacts, a contractor or subcontractor must communicate in a timely fashion that it encountered a problem or barrier to executing the work. Providing notice allows the owner and prime contractor to respond to the problem, perhaps by changing to a less expensive or more readily available material. Or, it allows them to eliminate or pause that portion of the scope of work if it is not on the critical path. Changes should be formalized with an additive or a deductive change order.

An example of the notice provision can be found in AIA Document A201-2007:

“§15.1.2. Claims by either the Owner or Contractor must be initiated by written notice to the other party and to the Initial Decision Maker with a copy sent to the architect if the Architect is not serving as the Initial Decision Maker. Claims by either party but be initiated within 21 days after occurrence of the event giving rise to such Claim or within 21 days after the claimant first recognizes the condition giving rise to the Claim, whichever is later.”

As described in previous sections of this article, the above notice provision can be revised and tailored to needs specific to the parties and the project.

Termination

Another key aspect of navigating construction supply chain issues is the inclusion of a termination provision. Termination provisions are pivotal and must be contemplated by all parties.

For example, if an owner or contractor is concerned that escalating material costs may result in unaffordable project costs, it should incorporate termination for convenience for default provisions in the contract. While contractors may not agree to the termination clause, contractors may agree to a termination provision that expressly states that if the contractor is substantially burdened economically due to the material increases, it may terminate the contract. Owners, contractors, and subcontractors should work together to address these supply chain issues to protect each member of the construction team from insolvency.

An example of a termination provision by the contractor from AIA A201-2007 is as follows:

“§14.1.1 The Contractor may terminate the Contract if the Work is stopped for a period of 30 consecutive days through no act or fault of the Contractor or a Subcontractor, Sub-subcontractor or their agents or employees or any persons or entities performing portions of the Work under direct or indirect contract with the Contractor, for any of the following reasons…

.2 An act of government, such as declaration of national emergency that requires all Work to be stopped…

.4 The Owner has failed to furnish the Contractor promptly, upon the Contractor’s request, reasonable evidence as required by Section 2.2.1.”

Parties to the contract can add to the list of reasons for termination any issues that may arise due to material supply chain issues and material costs.

Contractual Methods of Coordination as a Construction Project Team

It is particularly important in this industry to maintain the relationships built during each project. There are ways for the team to coordinate with one another to share the burden of supply chain-related issues and help keep the working relationships alive.

In the past, owners have held minor risk of material price increases, but in the current environment there is increased risk for owners too. Previously, some owners have competitively bid projects and awarded the job to the lowest bidder. However, with project risks increasing in scope and scale, there is currently an increased likelihood that the lowest bid reflects an irresponsible commercial offer that the contractor cannot deliver.

Given this realization, some owners are moving to a scored proposal where the price is just part of the bidder’s score, and the remainder is a determination of their ability to complete the job. This is a good and long overdue change, but more changes are needed.

The supply chain issues that arise in construction projects should not be resolved with a “winner take all” approach. Below are methodologies that can help to make issues less contentious.

Construction Manager General Contractor

CMGC, sometimes referred to as CMGC, CM@Risk, CM-Constructor, is a model wherein the owner hires a construction manager during, or even prior to, the design phase to “value engineer” the project. The construction manager will then act as the general contractor for that project. A more detailed description follows in the next paragraph, but the US Federal Highway Administration sums up the benefits of this method below:

Utilizing the contractor’s unique construction expertise in the design phase can recommend for the contracting agency’s consideration innovative methods and industry best practices to accelerate project delivery and offer reduced costs and reduced schedule risks. [1]

The owner will hire the construction manager based on qualifications, experience, and best value. The construction manager then provides advice during the design phase related to constructability, methods, schedule input, identifying and managing risk, material procurement, etc. When the design is nearing completion, the construction manager provides a GMP to the owner for construction of the project. The owner can then retain an independent cost estimator to provide a separate estimate for the project. The construction manager’s estimate must typically be within 10% of the independent estimate.

Contracts in the CMGC structure are often GMP, but they can also include contingencies to be used for specific circumstances, such as material cost escalation over a given threshold—for example, a 10% price increase over an indexed price.

Integrated Project Delivery (“IPD”)

IPD involves a high level of teamwork using a single contract between the owner, the design team, the contractor, and even major subcontractors. This is a relatively innovative approach to construction projects that facilitates collaboration. The AIA’s 2007, “Integrated Project Delivery: A Guide,” defined IPD as:

A project delivery approach that integrates people, systems, business structures and practices into a process that collaboratively harness the talents and insights of all participants to optimize project results, increase value to the owner, reduce waste, and maximize efficiency through all phases of design, fabrication, and construction.

Under an IPD approach, all of the parties work collaboratively during the design process to determine the design, the materials to be used, and the timeline of the project. The parties then bulk-order the materials, often before the design phase is completed, eliminating, or reducing many material supply chain issues.

IPD is a newer construction project method, and construction parties are still navigating the practicability of IPD. Some advantages of IPD include the financial alignment of design and construction, financial performance based on overall project outcome not individual firm performance, giving each team “skin in the game” for activities during preconstruction, facilitating collaboration by removing traditional silos, and collaboratively developing new ways to deliver complex projects.

Disadvantages of IPD include, for example, the upfront investment required early in the project, a diminishing return on preconstruction spending if design or permits take longer than planned, required project complexity to realize a savings after the initial investment, owners not having a firm fixed cap on cost at the start of the project, and multi-party contracts are typically not used for public owners.

Owners should weigh these pros and cons when considering an IPD approach for their project.

Partnering

Partnering is another new type of collaborative method that works to achieve measurable results through agreements and productive working partnerships. Partnering begins with the design phase of the project, and parties agree to work towards common goals and objectives. All parties should express their desire to perform the project under a partnering agreement. Owners should mention the use of this process in the project specifications and bid documents.

Typically, a pre-bid conference will include a presentation on partnering. At the meeting, the participants will agree to a partnering charter that contains a list of goals and objectives for the project. The charter is a guide for cooperation—not a contract. There are periodic evaluations to ensure the parties are maintaining their commitments to the partnering process. The charter also commits teams to dispute resolution, often to mediation, to retain open communications to decide issues as they come up during the project to expedite the schedule. The charter can include an agreed process for expedited review of submittals involving material supply chain issues.

The “pros” of the partnering approach in solving construction supply chain issues are that it redirects energy to focus on achieving project goals, encourages positive working relationships. It also helps to avoid excessive costs of claims and litigation, improves accountability, and gathers lessons learned by the team at closeout. In terms of “cons,” partnering is cost prohibitive for smaller projects, requires major commitment to change by project parties, and open communication may be inhibited when one partner also works with another partner’s competitor.

When All Else Fails – Legal Issues that Arise in a Litigious Dispute

The above methods are ways to assist with dispute avoidance. However, if litigation is unavoidable, there are legal theories that may be argued in cases that involve material supply chain issues. While no two construction cases are the same, here are some legal arguments that may arise:

Doctrine of Impracticability

The Impracticability doctrine arises in circumstances where performance may be impracticable because of extreme and unreasonable difficulty, expense, injury, or loss to one of the parties involved. If the cost of materials or the shortage of materials make it unreasonably difficult or expensive for a party to perform the contract, they can argue that performance was impracticable.

Depending on the state, a party must make a showing to be discharged from the contract. For example, a party must show (i) after entering into the contract, an unexpected intervening event occurs, (ii) the non-occurrence of the intervening event was a basic assumption underlying the contract, and (iii) the intervening event made performance wholly impossible or objectively economically impracticable.

Doctrine of Mutual Mistake

A mutual mistake can occur when parties to a contract are both mistaken about the same material fact within the contract, and the contract is invalid. A party must show that (1) there was a mistake; (2) that the mistake must be material, meaning that it must concern substantive characteristics of the subject of the contract; and (3) the mistake was mutual, meaning both parties had the same mistaken belief.

Remedies

Equitable Reformation and Rescission are remedies that a party can seek to avoid responsibility under the contract.

If a party can show misrepresentation, fraud, undue pressure to sign the contract, or something else that may invalidate the contract from forming, the contract can be rescinded or terminated, meaning the contract is set aside so that the parties can be restored as much as possible to their original position.

Equitable Reformation allows a contract to be modified if a party can show that (1) there was an antecedent agreement to which the contract can be reformed; (2) that there was a mutual mistake or a unilateral mistake on the part of the party seeking reformation and inequitable conduct on the part of the other party; and (3) that the party seeking reformation is not guilty of gross negligence. If these elements can be shown, the court will modify the contract to reflect the parties’ true intent.

Damages Analysis

The specific damages and impacts experienced on a project without an escalation clause will be dependent on the facts of the case. For example, the contractor may be unable to get quotes on the quantity of material required due to scarcity, or material may be available at double the price quoted when assembling the bid. For major materials, such as steel, this may put the contractor in the position where the project is no longer financially feasible.

If materials are simply unavailable due to factory shutdowns, sanctions, supplier default, or some other reason beyond the contractor’s control, the owner and contractor may be forced to seek out alternative materials to substitute, often at increased cost.

If material costs have increased to the point where they jeopardize the project, the contractor may seek other sources for those same materials, or they may seek approval for an alternate, and typically less desirable, material to substitute.

Whether materials are unavailable or prohibitively expensive, delay is likely to result as the contractor searches for a solution. Critical path delays will likely result in extended overhead costs and may expose the contractor to assessment of liquidated damages. Contractors that are delayed may be contractually required to accelerate to recover the lost time. Increased costs resulting from acceleration could include overtime, increased payroll, added equipment costs, and lost efficiency coming from numerous sources including fatigue, trade stacking, etc.

Contractors that can anticipate facing supply chain issues like escalating prices and/or material shortages may attempt to purchase materials early. Setting aside the risk that material prices may end up falling instead of continuing to rise, the decision to purchase early will result in additional costs for storage and for double-handling. Taking the risk of purchasing materials early can have the added benefit of reducing or eliminating delays and the added costs that result from delays. Given this benefit, it may be in the interest of the owner to provide advance payment for certain major items facilitating the contractor’s early purchasing.

No matter the type of impact or specific form of increased costs, maintaining proper and detailed records and communicating in a timely manner will assist the contractor’s effort to recoup cost increases or time extensions flowing from increased material costs. One practical example of a detailed record that can be used to document delay analysis impacts associated with procurement issues are the project schedules.

Ideally, the contemporaneously maintained schedule updates would reflect the original plan for procurement, the subsequent delay events, including specific ties to the impacted activities, and an accurate as-built record of project events. Broadly speaking, as delays and cost impacts become apparent, the contractor should document and communicate the ways in which material cost increases are impacting its ability to execute its contractual obligations, while working to identify reasonable mitigation efforts.

Expert Construction Dispute Support With HKA

Boasting over four decades of expertise in construction and engineering, HKA is an industry-leading consultancy with a global presence. Our array of services spans dispute resolution, claims consultancy, advisory support, and construction expert witness services. At all stages of a construction or engineering project, we provide the analysis, guidance and support to aid you in the case of a dispute.

We help a range of stakeholders, including owners, operators, contractors, subcontractors, law firms, and government agencies, with our services meticulously tailored to meet their unique needs.

HKA is the trusted partner you can rely on to successfully navigate the complexities of construction and engineering disputes.

About the author:

Bryan Van Lenten is a licensed professional engineer with over 15 years of experience in civil projects, specializing in engineering, design, and construction. He has provided expert reports for disputes exceeding $800 million in the USA, Middle East, and Australia, covering areas such as construction management, disruption, productivity impacts, delay, and cost.

With a background in structural design across various structures, Bryan is an expert in construction delay and damages, offering extensive experience in delay analysis and quantifying productivity impacts. He is licensed in multiple states, a certified National Highway Institute (NHI) instructor, and has presented seminars on construction claims avoidance to departments of transport nationwide.

[1] FHWA Docket No. FHWA-2015-0009, Federal Register Vol 81, No. 232, 12/2/2016, Pages 86928-86947

This publication presents the views, thoughts or opinions of the author and not necessarily those of HKA. Whilst we take every care to ensure the accuracy of this information at the time of publication, the content is not intended to deal with all aspects of the subject referred to, should not be relied upon and does not constitute advice of any kind. This publication is protected by copyright © 2024 HKA Global Ltd.