Navigating Data Centre Fire Protection: Understanding Lithium-ion (Li-ion) Battery Hazards

22nd April 2024

As published for the Fire Protection Association Journal Feb 24

There has been an increase recently in the number of fires that are being reported in the press in relation to Li-ion batteries. The issues related to these fires stem from either defective battery installations or insufficient or improper fire suppression being specified.

I recently acted as an expert witness in a case where the applicable guidance documents, at first sight, did not require the provision of fire suppression in battery rooms. The applicable guidance document was written not so long ago but did not consider the specific risks inherent to Li-ion batteries.

In another case, clean agent fire suppression was specified as coverage for battery rooms. The specification was again based on the applicable standards and guidance documents. Unfortunately, a fire occurred, and the clean agent system did not extinguish or control the fire.

These apparent faults in the specification and guidance documents could have been avoided if there had been a fire engineering analysis, or by looking a bit further and consulting other standards and literature, and delving a bit deeper into the subject. What is surprising, and at the same time concerning, is that a dedicated fire engineering team was involved in the design and construction of the project.

In this article, I illustrate the specific risks inherent to Li-ion batteries, the potential risk mitigations, and the guidance from codes and standards. I will conclude with my opinion on what the role of the fire engineer should be in dealing with projects where specific risks exist such as those inherent to Li-ion batteries.

Li-ion Batteries in Data Centres

Li-ion batteries are becoming increasingly popular in data centres due to their high energy density, longer lifespan, and lower maintenance costs compared to traditional batteries.

In data centres, Li-ion batteries are used as a backup power source for uninterruptible power supply (UPS) systems. They are preferred over other batteries because they can provide more power in less space. Li-ion batteries are also faster to charge and discharge than other battery types, which makes them ideal for use in data centres where power outages can cause significant damage.

Li-ion Battery Hazards

However, Li-ion batteries are still a relatively new technology, and there are still many unknowns regarding their performance and reliability.

With regard to data centre fire protection, the risk of thermal runaway, which can cause the battery to overheat and catch fire, is a concern. Therefore, it is important to ensure that Li-ion batteries are used in a safe and controlled environment.

Thermal runaway reaction

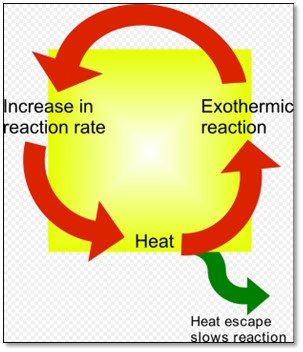

Chemical reactions are either endothermic or exothermic. In layman’s terms, endothermic reactions need energy to happen, exothermic reactions release energy. Many chemical reactions including the chemical reaction that happens in case of many Li-ion incidents are exothermic.

The picture below shows the exothermic reaction process which accelerates when the released heat cannot be dissipated quickly enough.

Figure extracted from Wikipedia – Thermal runaway.

Thermal runaway is a process in which an exothermic reaction goes out of control, causing a further increase in temperature and hence a further rapid increase in the reaction rate.

In Li-ion batteries, thermal runaway is a phenomenon in which the lithium-ion cell enters an uncontrollable, self-heating state. This can occur when a lithium-ion battery is damaged, overcharged, or exposed to high temperatures. According to UL Research Institutes[1]UL (Underwriters Laboratories) Research Institutes is a leading independent safety science organization with global reach., during thermal runaway, the battery generates heat at a rate several times higher than the rate at which heat dissipates from the cell. The cell reaches thermal runaway when its temperature rises uncontrollably at a rate greater than 20°C per minute with maximum temperatures reaching greater than 300°C accompanied by gas and/or electrolyte venting, smoke or fire or a combination of all.

The risks associated with thermal runaways include the ejection of gas, shrapnel, and/or particulates, extremely high temperatures, smoke, and fire.

How to stop a thermal runaway reaction

Knowing how to stop a thermal runaway reaction is vital for data centre fire protection. To stop a reaction, it is important to remove the heat source and cool the reaction mixture as quickly as possible. In chemical processes, this is typically done by using a heat exchanger, or temperature control device, by adding a reaction inhibitor or quenching the reaction by cooling, or by directly dumping the reaction mixture into the quenching liquid itself.

Fire suppressions systems

In data centres, clean agent gaseous fire suppression systems are often used as they are generally suitable for electrically energised fires. The application of water from deluge or sprinkler systems is often discouraged because it allegedly is unsuitable to fight electrically energised fires. It can cause short-circuits increasing the risk of electrocution for persons in the room of electrically energised equipment. It is also claimed that water can cause more damage than the fire itself.

Fires are suppressed by removing or disrupting one of three elements needed to sustain a fire: heat, oxygen, or the fuel source.

Clean agent fire suppression systems may not be effective in stopping a thermal runaway reaction as a clean agent fire suppression system does not provide the required cooling. The clean agent fire suppression may reduce the oxygen concentration in the room, however, the thermal runaway is a chemical reaction that does not stop by simply removing or reducing the oxygen levels.

In other words, a clean agent fire suppression system may temporarily reduce or even extinguish the fire, it will not stop the runaway reaction with the result that a fire that is suppressed temporarily will re-ignite again.

Guidance documents

Initially, the absence of specific safety protocols tailored to Li-ion batteries led to incidents involving thermal runaway, fire outbreaks, and explosions. These incidents prompted a concerted effort by regulatory bodies, industry experts, and research organisations to establish comprehensive safety guidance and standards.

The National Fire Protection Association (NFPA), Underwriters Laboratories (UL), and Factory Mutual (FM) were among the pioneering organizations that took a proactive role in formulating guidelines to address Li-ion battery hazards. NFPA’s NFPA 855[2]Standard for the Installation of stationary energy storage systems, UL’s UL 9540[3]Energy storage systems and equipment, and FM’s Property Loss Prevention data sheets 5-32[4]Data centres and related facilities (FM DS 5-32) are exemplar standards developed to ensure the safe installation and use of energy storage systems, including Li-ion batteries.

NFPA 855 outlines requirements for the installation, design, and maintenance of energy storage systems, emphasizing fire safety measures. It covers aspects such as thermal runaway mitigation, proper ventilation, fire suppression systems, and emergency response planning, thereby significantly reducing fire risks associated with Li-ion batteries in various settings.

More specifically, NFPA 855 defines requirements regarding the compartmentation of battery rooms and it states that the battery room should be separated from the data centre room where the maximum stored energy exceeds 600 kWatt Hour.

The standard states that sprinkler systems are highly recommended and formulate the design criteria to which the sprinkler system must comply in the case of Li-Ion battery rooms.

Note that NFPA 855, like most important NFPA standards, undergoes updates every 3 years.

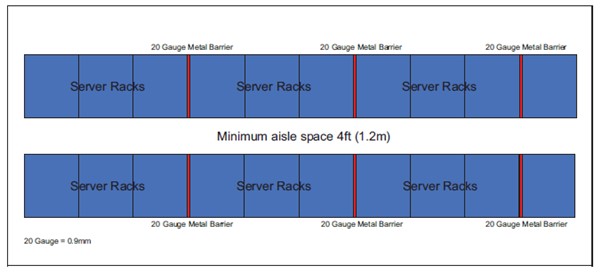

Similar to NFPA 855, FM DS 5-32 outlines design requirements. It specifically states not to use clean agent or water mist systems. It also defines how server racks where Li-ion distributed power systems are used need to be constructed as indicated in the below figure extracted from FM DS 5-32.

Figure extracted from FM DS 5-32

Note the required metal barriers after every 3rd server rack as a measure to mitigate the impact of a possible thermal runaway.

UL 9540 focuses on evaluating the safety of energy storage systems by assessing their electrical, mechanical, and thermal stability. UL certification following rigorous testing procedures assures the safety and reliability of Li-ion battery systems.

Continuous advancements in technology and ongoing research have further contributed to the development of updated safety standards. Emerging innovations, such as smart battery management systems, and improved thermal management techniques, continue to shape the evolution of safety protocols for Li-ion batteries.

Researchers are also working on the battery materials themselves by replacing flammable liquid electrolytes with more stable, solid electrolyte materials such as non-flammable gels, inorganic glass, and solid polymers to create solid-state batteries. They are also developing cathodes that release less oxygen when they break down and separators that can withstand high temperatures without melting.

These technological innovations, when implemented, will reduce or perhaps eliminate certain fire risks such that revisions to the current standards will be required.

Conclusion

The proliferation of lithium-ion (Li-ion) batteries within the technological landscape has ushered in an era of enhanced energy storage.

The allure of Li-ion batteries stems from their superior energy density, prolonged lifespan, and faster charging capabilities compared to traditional battery technologies. This allure, however, comes hand in hand with inherent risks.

Thermal runaway stands as the paramount concern. It refers to an uncontrollable increase in temperature within the battery, often cascading into an irreversible chain reaction of heat generation and gas release.

Though Li-ion technology is relatively new, fire safety guidance documents and standards are available. While there is still room for development, as with most fire safety codes and standards, the guidance is already detailed, and strict implementation will contribute greatly in reducing the fire risk.

Company, industry-specific, or local government standards are not always up to date with the latest developments and therefore blindly following those standards can lead to wrong design and serious consequences.

A fire engineer should therefore always consider the specific fire risks associated with equipment.

A fire engineer may not be a specialist in Li-ion battery risks, however, a simple search on the internet shows that a thermal runaway reaction is a concern with Li-ion batteries. Even when the exact details of a thermal runaway reaction are not known, it should not be difficult for a fire engineer to understand that special precautions such as separation, compartmentation, and adequate fire protection are needed to provide effective risk mitigation.

As safer Li-ion batteries or battery technology is still developing, it is important for the fire engineer to keep using the latest information available when developing the fire mitigation strategies inherent to Li-ion batteries.

About the Author

Peter Van Gorp has 30 years of experience working as a fire safety engineer. He has provided consultancy, expert witness and advisory services in locations across the world including, Middle East, the UK, Europe and Africa. Peter leads HKA’s global Forensic Technical Services (FTS) fire engineering team.

He acts as an independent expert witness on fire safety matters within various industries including Buildings, Infrastructure, Energy and Oil and Gas. He has been instructed as an independent expert on numerous occasions, for matters in international arbitration, adjudication and litigation.

HKA Services

HKA is a leading global consultancy in risk mitigation, dispute resolution, expert witness and litigation support services.

We collaborate with various stakeholders including owners, operators, contractors, subcontractors, law firms and government agencies, tailoring our services to meet their individual requirements.

Contact us to enquire about our market-leading expert services.

This publication presents the views, thoughts or opinions of the author and not necessarily those of HKA. Whilst we take every care to ensure the accuracy of this information at the time of publication, the content is not intended to deal with all aspects of the subject referred to, should not be relied upon and does not constitute advice of any kind. This publication is protected by copyright © 2024 HKA Global Ltd.